In the maritime industry, the efficiency and safety of ship mooring operations are paramount. One essential piece of equipment that plays a crucial role in this process is the air winch. In this blog post, we will delve into the world of air winches, comparing them to electric winches for ship mooring and exploring the ideal environments for marine air winches.

What Is An Air Winch?

An air winch, also known as a pneumatic winch, is a powerful tool commonly employed as a mooring winch in marine applications. These winches utilize compressed air as their energy source, making them versatile and reliable for various heavy-duty lifting and pulling tasks.

Air Winch Working Principle

An air winch uses compressed air as its energy source, supplied from a tank or compressor. The compressed air powers an air motor within the winch, converting the stored energy into mechanical power.

The air motor drives a drum connected to a gear mechanism, controlling the speed and direction of the winch. This setup allows for precise handling of ropes or cables used in mooring operations.

The drum is typically wrapped with a wire rope or cable. When the winch is activated, the drum rotates, either winding in or letting out the rope to secure or release the ship during mooring.

Control systems are integrated into the winch to regulate speed and direction, ensuring smooth and controlled mooring operations. Safety features such as overload protection and emergency stops are often included to enhance operational safety.

In summary, an air winch uses compressed air to power its motor, drive a drum with a gear mechanism, and control the winding of ropes or cables for secure ship mooring, all while maintaining operational efficiency and safety.

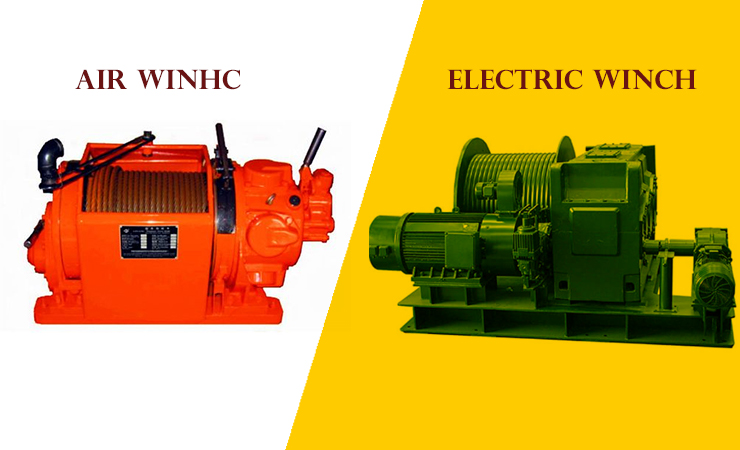

Marine Air Winch vs. Electric Winch

When deliberating on the optimal winching system for marine and industrial use, the decision between an air mooring winch and an electric mooring winch stands as a critical determinant of operational efficacy and safety adherence. Each winch, propelled by disparate power sources, presents a distinctive array of benefits and challenges that necessitate a comprehensive comparative assessment. By dissecting the functionalities and characteristics of these two winch types, we can unravel their operational intricacies and ascertain their appropriateness for a spectrum of operational settings and requirements.

Power Source

The power sources for a marine air winch for mooring and an electric mooring winch differ significantly. The pneumatic winch relies on compressed air for its operation, making it a suitable choice for environments where electricity might not be readily accessible or safe, particularly in marine settings. However, utilizing a Marine Air Winch necessitates access to compressed air sources, potentially requiring additional equipment like air compressors.

An electric mooring winch operates using electricity as its primary power source. This makes it a widely available and convenient option for a variety of applications. Nonetheless, the electric mooring winch is susceptible to electrical hazards in specific environments and demands a stable power supply for optimal performance and safety.

Efficiency and Performance

Marine Air Winch for Mooring:

- The Marine Air Winch for Mooring may exhibit slightly lower efficiency levels when compared to electric winches. This variance is contingent upon factors such as the consistency and pressure of the air supply.

- Despite potential efficiency discrepancies, the Marine Air Winch for Mooring excels in environments where the advantages of utilizing compressed air outweigh any minor efficiency differences.

- One notable advantage of the pneumatic winch lies in its capacity to operate safely in situations where the presence of electricity poses risks, making it a reliable choice for marine settings or areas where electrical equipment might not be viable due to safety concerns.

Electric Mooring Winch:

- In contrast, the electric mooring winch is renowned for offering consistent and reliable performance across various applications.

- With higher efficiency levels in comparison to air winches, the electric mooring winch ensures operations run smoothly, with predictable outcomes.

Choose Air Winch For Ship Mooring

In marine applications, the need for an air operated winch for ship mooring arises in specific scenarios where the use of electricity is impractical or unsafe. Here are instances when an air winch is preferred for ship mooring concerning specific ship types and environments:

Specific Ship Types

Oil Tankers and Gas Carriers:

- Due to the flammable nature of their cargo, oil tankers and gas carriers often require non-electric winches like air winches to prevent potential ignition sources during mooring operations.

Research Vessels:

- Research vessels conducting scientific missions in sensitive marine ecosystems may opt for air operated winches to minimize electrical hazards and environmental risks during mooring procedures.

Operating Environments

Offshore Platforms:

- In offshore environments such as oil rigs or drilling platforms, where the presence of flammable gases poses a significant risk, air winches are preferred for ship mooring to mitigate potential ignition hazards.

Harbors with Corrosive Conditions:

- Harbors with high levels of saltwater exposure or corrosive elements may opt for air winches to avoid damage to electrical components and ensure reliable mooring operations over an extended period.

Subsea Operations:

- Subsea vessels and equipment engaged in underwater operations may utilize air winches for ship mooring due to the challenges of maintaining electrical equipment in submerged environments.

Safety Considerations

Explosive Atmospheres:

- Environments where explosive gases or vapors are present necessitate the use of air operated winches to prevent the risk of electrical sparks or arcs during ship mooring activities.

Emergency Response Vessels:

- Emergency response vessels, where rapid and reliable mooring is crucial, may rely on air winches for ship mooring to ensure operational readiness in critical situations.