The ship ventilation system is helpful in maritime operations. It ensures that the crew members are healthy and safe in the open waters. However, just like other complex systems, these ventilation systems need to face extremely hard challenges.

Components Of Ship Ventilation System

A ship ventilation system typically includes several fundamental components. These components work together to provide a healthy and comfortable environment for people on ships.

Ventilation Fans: These fans are tasked with circulating air throughout various sections of the ship. By moving fresh air and removing stale air, they ensure proper air exchange within enclosed spaces.

Air Ducts: Ducts distribute air from the ventilation fans to different areas of the vessel, ensuring that air reaches all compartments, including cabins, engine rooms, and communal spaces.

Filters: Filters play a crucial role in removing contaminants, dust, and particles from the air. They are instrumental in improving air quality by ensuring that the circulated air is clean and safe to breathe.

Monitoring Systems: Modern ventilation systems are equipped with advanced monitoring systems that regulate and optimize system performance. These systems monitor air quality, temperature, humidity levels, and overall system efficiency.

Exhaust Ports: Exhaust ports are vital for expelling stale air and contaminants from the ship. They facilitate the continuous flow of fresh air by allowing the escape of used air from different compartments.

Ventilation Controls: Crew members use ventilation controls to adjust system settings according to the ship’s requirements. These controls regulate air circulation, temperature, and humidity levels to maintain a comfortable onboard environment.

Insulation: Proper insulation is essential for preventing heat loss or gain through the ventilation system. Insulation materials help maintain the desired temperature within the ship and improve energy efficiency.

Each component showcases the respective crucial functions and efficiency in the ventilation system onboard ship. The purpose is to guarantee that everyone on the boat can be safe, healthy, and comfortable.

Varieties of Ventilation Fans Utilized in Ship Ventilation Systems

In a marine ventilation system, the principle is to use various ventilation fans to ensure the air circulation and ventilation of the whole boat. Commonly, there are three kinds of ventilation fans in ship ventilation systems. They are centrifugal fans, axial fans, and diagonal flow fans.

Centrifugal Fans

Centrifugal fans are commonly used in ship ventilation systems due to their ability to generate high-pressure airflow. These fans operate by increasing the speed of the air stream and redirecting it using centrifugal force. Centrifugal fans are efficient for applications requiring airflow against higher static pressures, making them suitable for ventilation systems in ships where ducts may have resistance or bends.

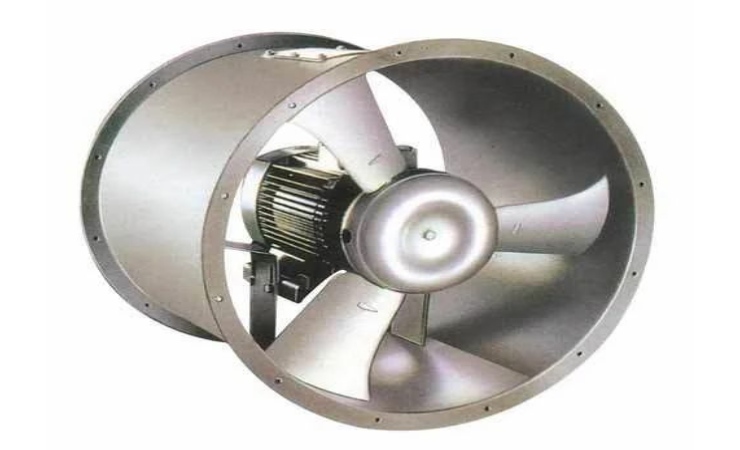

Axial Fans

Axial fans are another type of fan frequently employed in ventilation systems onboard ship. These fans operate by drawing air into the fan and discharging it in the same axial direction. Axial fans are known for their high airflow capacity and are particularly useful in applications where a large volume of air needs to be circulated at lower pressures. They are commonly used for general ventilation purposes on ships.

Diagonal Flow Fans

Diagonal flow fans, also known as mixed flow fans, combine features of both axial and centrifugal fans. These fans operate by drawing air in axially and then deflecting it radially using blades set at an angle. Diagonal flow fans offer a balance between the airflow capacity of axial fans and the pressure generation of centrifugal fans. They are suitable for applications in ventilation systems in ships that require a mix of high airflow and moderate pressure.

Ship Ventilation System Challenges and Solutions with Different Fan Types

In ship ventilation systems, centrifugal fans are skilled in handling high static pressure. But when the pipes are obstructed, there may be some airflow issues. That means regular maintenance including keep the pipes clean and clear, and balancing the system can be helpful to maintain their performance best.

In contrast, axial fans are prominent in the aspect of transporting numerous volumes of air. Nevertheless, they are still possible to come across difficulties in pressure generation. In order to solve the problem, ship operators can try to install supplemental fans or booster fans to overcome the pressure limitations. Otherwise, making sure that the airflow path is clear and direct is also helpful to enhance the efficiency of axial fans in marine ventilation systems.

Diagonal flow fans keep the balance between airflow and pressure. However, the complexity of the design may need specific maintenance and troubleshooting procedures. Trimming the blade angles of diagonal flow fans is helpful in achieving the balance between airflow and pressure. Similarly, regular inspection and maintenance also help diagonal flow fans to operate.

Thinking about the special properties and capabilities of centrifugal, axial, and diagonal flow fans carefully, marine operators will be able to solve the challenges in ventilation systems, refine the airflow, adjust the pressure, and keep the integral efficiency in ship systems actively.

Frequent Challenges and Remedies in Ship Ventilation Systems

Within ventilation systems onboard ship, challenges often arise from issues such as inadequate airflow distribution caused by blocked air ducts or improper fan operation. Clogged filters can impede air circulation, leading to reduced air quality. Malfunctioning fans, whether centrifugal, axial, or diagonal, disrupt overall ventilation efficiency. Poor air quality stems from insufficient ventilation, resulting in stale or contaminated air circulating within the ship.

For the sake of dealing with these worries, we can adopt specific measures. First, we should implement the maintenance plans regularly, and clean the obstructions in the air ducts, then try to adjust the fan settings in order to realize the optimal distribution of airflow. Besides, filter maintenance procedure is used for keeping the air quality and ensuring to clean and replace filters in time. Last, it is also crucial to repair or replace the faulted fans to recover the conventional ventilation function. Meanwhile, using sensors to monitor the air quality level is also useful to find and correct potential mistakes so as to provide a cosy circumstance for all passengers.