About product

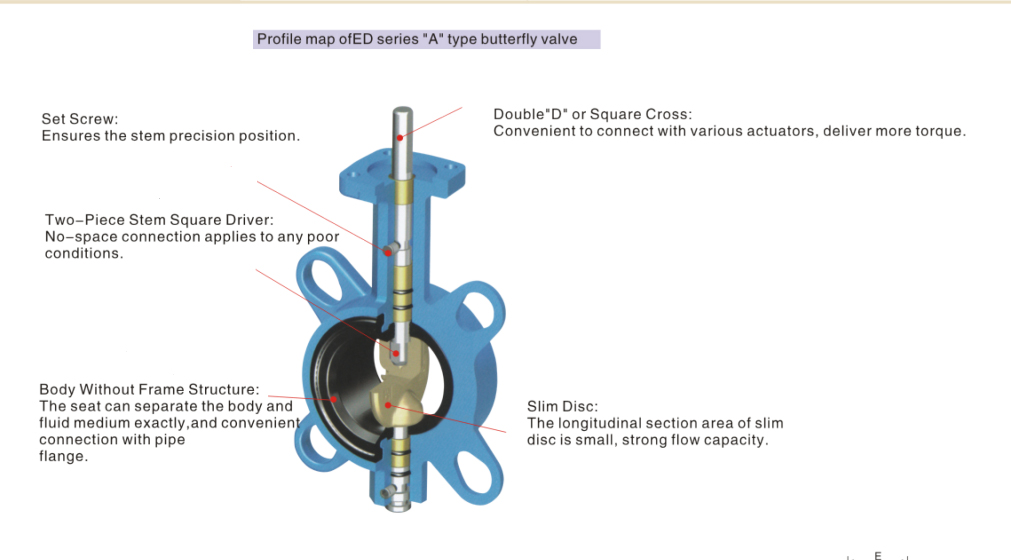

Marine ED series wafer butterfly valve, designed for marine applications. The stem head design of Double “D” or Square cross allows for easy connection with various actuators, enabling the wafer butterfly valve to deliver more torque. Additionally, the two-piece stem square driver provides a secure and reliable connection, making it suitable for challenging conditions.

With a body structure that eliminates the need for a frame, the wafer valve allows for precise separation of the seat from the body, ensuring optimal sealing with the fluid medium. It also facilitates convenient connection with pipe flanges during installation.

- Temperature range: -23℃ to 130℃

- Shot time temperature range: -30℃ to 150℃