About product

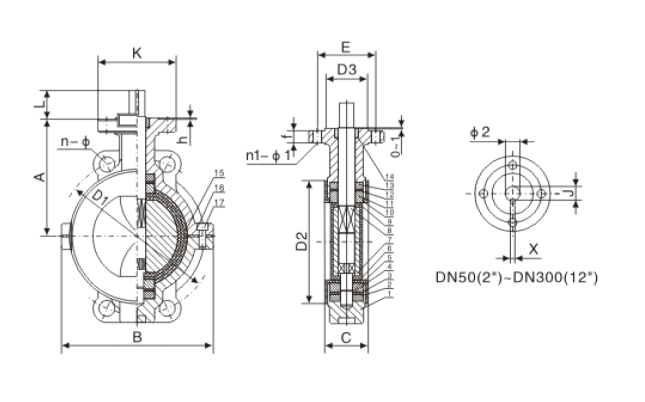

The marine FD series wafer butterfly valve is a type of wafer valve designed for corrosive media, particularly strong acids like sulfuric acid and aqua regia. It features a PTFE (polytetrafluoroethylene) lined structure, which provides excellent corrosion resistance and prevents the wafer butterfly valve from polluting the media within the pipeline.

- Two-way installation

- Zero leakage

- Corrosion resistance

- Light weight and small size

- Low cost

- Easy installation

- Split-type structure