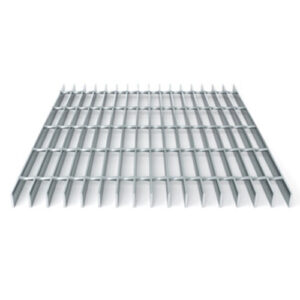

About product

Marine fiberglass grating stands out as the superior choice for deck surfaces on ships, jetties, pontoons, piers, walkways, platforms, staircases, and landings. With its exceptional performance, FRP grating has earned a stellar reputation in the marine industry due to its resilience against the harshest marine conditions — from wetness to oiliness to icy conditions.

The structural integrity of FRP grating is unparalleled, boasting impressive strength, impact resistance, and resistance to sagging, surpassing the limitations of composite wood. Moreover, fiberglass grate is significantly lighter than steel, facilitating easy on-site customization as needed.