About product

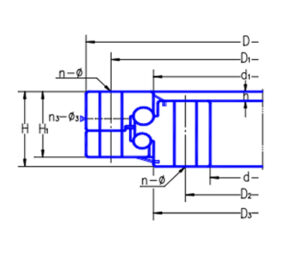

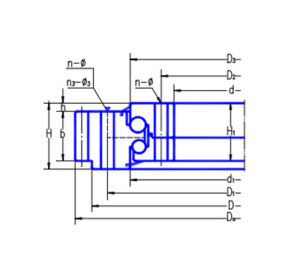

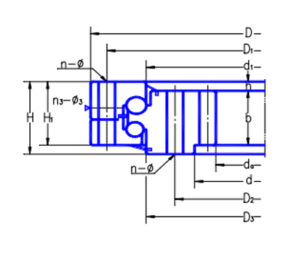

The Marine Double-row Ball Slewing Ring, incorporating same diameter balls, finds widespread use in wind-driven generators and concrete pump trucks. Specifically, in wind-driven generators, it is commonly installed at the propeller’s base to facilitate variable pitch control, requiring zero clearance, high running accuracy, and a significant starting friction moment. This durable and precise bearing fulfills the demanding requirements of these applications effectively.

- Ring Material: 42CrMo, 50Mn, or C45 steel

- Ball/Roller Material: GCr15 steel

- Cage Material: Either steel 20 or ZL102 cast aluminum alloy

- Spacer Material: Nylon 6 or nylon 66

- Quenching Hardness of Raceway: Ranging from HRC55 to HRC62