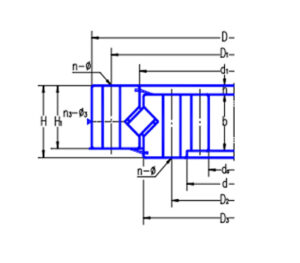

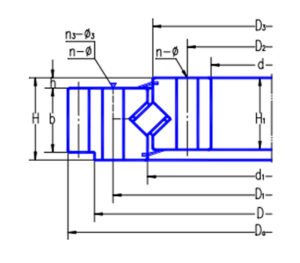

About product

The Marine Single-row Crossed Roller Turntable Bearing is a compact and lightweight solution designed for high precision and small assembling clearance. With its crossed roller arrangement, it can effectively accommodate high axial, radial, and tilting moment loads. This slew bearing is ideal for applications in hoisting equipment and various engineering machinery, offering reliability and performance.

- No gear

- Internal gear

- External gear