About product

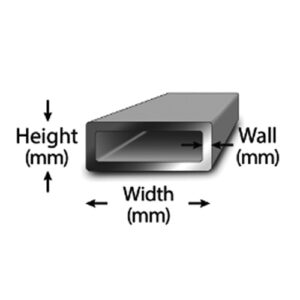

Marine stainless steel rectangular tube is specifically designed for use in marine environments, where it is exposed to moisture, saltwater, and other corrosive elements. The tube is made from stainless steel, which is an alloy containing a high percentage of chromium. The chromium content provides excellent corrosion resistance, making stainless steel ideal for marine applications.

The rectangular shape of the tubing offers structural strength and versatility, allowing it to be used in various marine-related applications such as boat railings, frames, supports, and structures. The rectangular design provides stability and can be easily integrated into different configurations.