About product

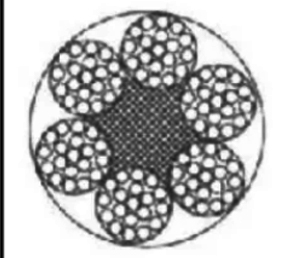

The 6 x 19 fiber core wire rope is a specific type of steel wire rope that finds application in marine environments. With its construction consisting of six strands, each containing 19 individual wires, this steel cable strikes a balance between strength and flexibility. It is designed to withstand heavy loads and demanding tasks, making it ideal for various industries.

- Excellent corrosion resistance in marine environments.

- Enhanced flexibility for easier handling and installation.

- Minimizes damage to equipment, reducing maintenance costs.

- Specifically designed for marine applications.

- Versatile for various lifting, pulling, and securing tasks.