About product

Our lashing eye plates have a minimum breaking strength of 500 kN (kilonewtons). This specification indicates the maximum force the lashing eyes can withstand before breaking or failing. The high breaking strength ensures the reliability and safety of the lashing system during cargo transportation.

The lashing eyes are coated with a weldable workshop primer. This primer serves as a protective layer and facilitates easy welding during installation.

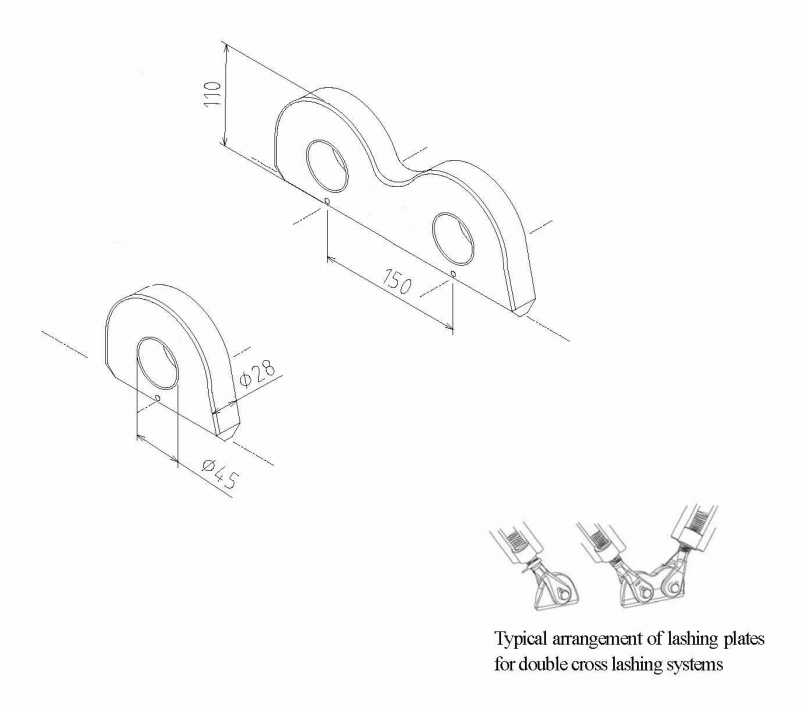

We offer a range of material and finish options for the lashing eyes. This includes various sizes and can be customized upon request. Our materials are selected for their strength, durability, and corrosion resistance.