About product

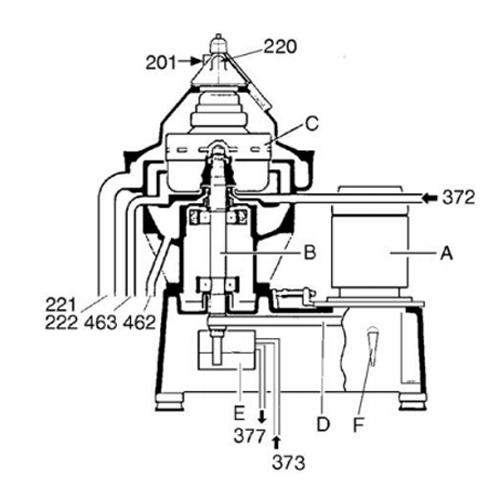

The KYDB304 Type Marine Oil Centrifuge is a high-speed oil water separator designed for both offshore and terrestrial applications. Its primary function is to remove water and solid particles, commonly referred to as sludge, from mineral oil. The centrifuge operates at high speeds to effectively separate the impurities from the oil. Clean oil is discharged continuously, ensuring a consistent supply of purified oil for various applications. On the other hand, the dirty residue, containing the separated water and solid particles, is discharged intermittently. This intermittent discharge allows for efficient removal of the accumulated sludge, ensuring optimal performance and longevity of the equipment.

- processing light oil: 1.5-5.5est/40℃

- diesel oil: 13cst/40℃

- heavy fuel oil: 30-380CST/50℃

- diesel engine or turbine lubricating oil