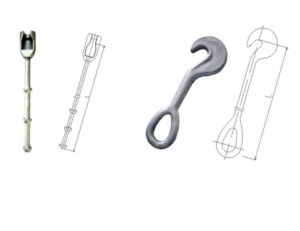

About product

Marine Container Extension Hooks are connectors used in container lashing systems. They serve as distance compensators for the rod connections in container lashing, reducing the number of rod types and turnbuckle screws required. This helps to lower costs and simplifies management in the container lashing process.

- Hot dip galvanised

- Min breaking loads tension 500 KN

- Other dimensions on request

- All item are approved by major classification societies