About product

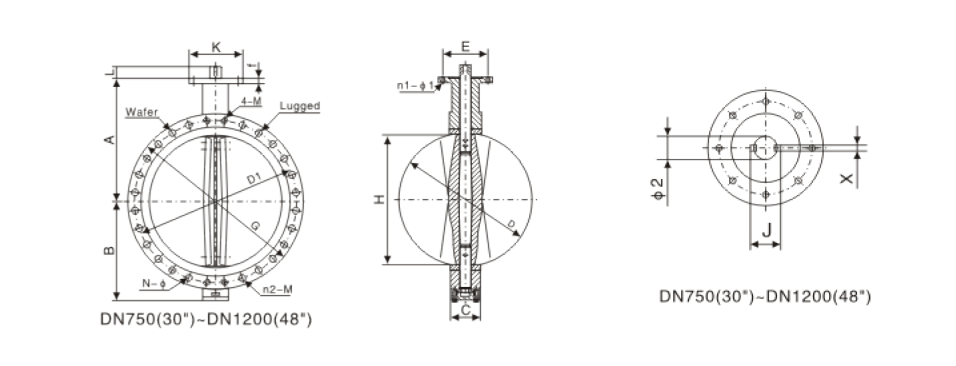

The FUD Series Hard Seated Butterfly Valve is designed with user-friendly features to facilitate installation, replacement, and maintenance. This butterfly valve is designed in a wafer pattern with flanges, it incorporates correcting holes on the flange, following standard guidelines, which make it easy to correct alignment during installation. The valve offers the choice between a through-bolt or a one-side bolt configuration, allowing for effortless replacement and maintenance.

Additionally, this ship valve is available with seat options such as phenolic-backed or aluminum-backed seats. These seats are non-collapsible, stretch-resistant, blowout-proof, and can be field-replaced when needed. These features enhance the overall convenience and reliability of the UD series hard-seated wafer valve in marine applications.