About product

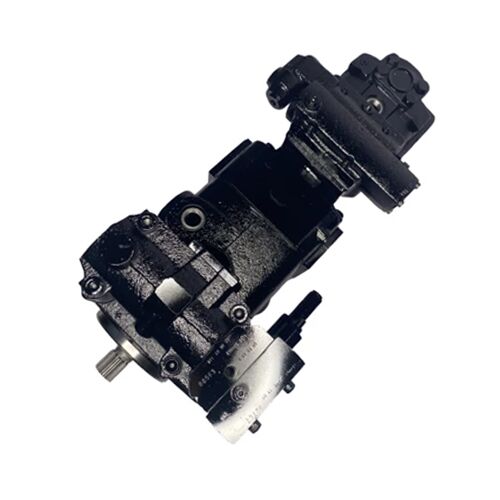

We specialize in providing Mitsubishi MK Pumps for a variety of marine applications. These Mitsubishi hydraulic pumps are designed to be lightweight, offer excellent self-suction capabilities, and operate quietly. They come in options such as low-pulse-pressure and burn-resistant hydraulic fluid types. Additionally, we offer various controllers with adjustable capacities to cater to different requirements.

There are various models of marine Mitsubishi hydraulic pumps, such as 1V-FH2B-MK-RFBLA20D11 and TMK-33A-M. These pumps are typically used for ship steering gears, cranes, and other equipment, ensuring the normal operation and function of the vessel.