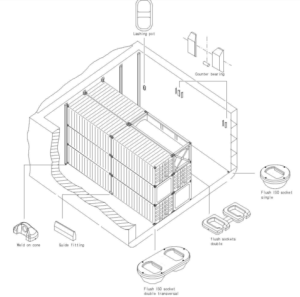

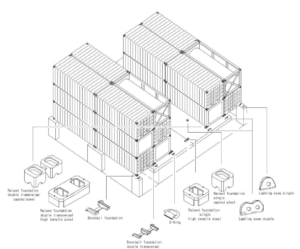

About product

This Container Raised Deck Socket type is designed to be welded onto the designated structure, ensuring a robust and long-lasting attachment. Its standardized height is set at 110mm, adhering to industry standards for container stacking. However, customization is available, allowing for different heights to be accommodated based on specific requirements.