About product

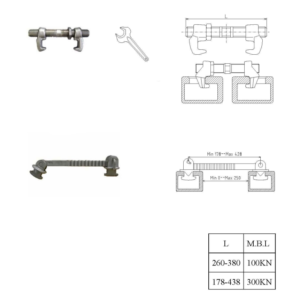

Bridge Fittings are devices used to connect the top containers of two adjacent stacks. They can be used on the deck or inside the cargo hold. These connectors are designed to withstand both tension and compression forces. They can be used with containers of varying spacing and are tightened using a central nut.

- Materials: Casting Steel

- Size: Customizable

- Certificate: BV, ABS, RINA, CCS, KR, NK and more