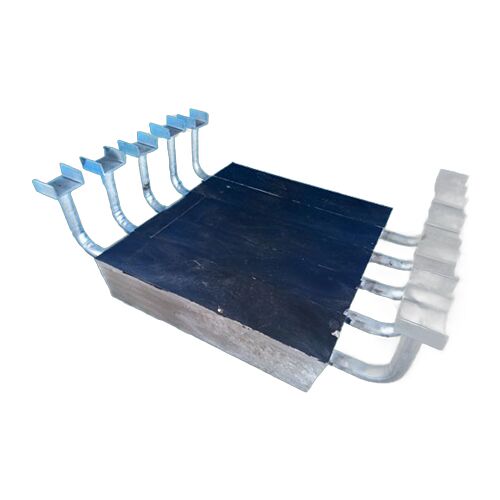

About product

Zinc anodes play a crucial role in providing heavy-duty corrosion protection for ports and offshore platforms during their construction phase. These anodes are specifically designed to withstand the harsh marine environment and are typically large and heavy due to the scale of the structures they protect.

During the construction of ports and offshore platforms, zinc anodes are strategically installed on various submerged or exposed surfaces. Their size and weight ensure long-lasting protection against corrosion, extending the lifespan of critical infrastructure.