About product

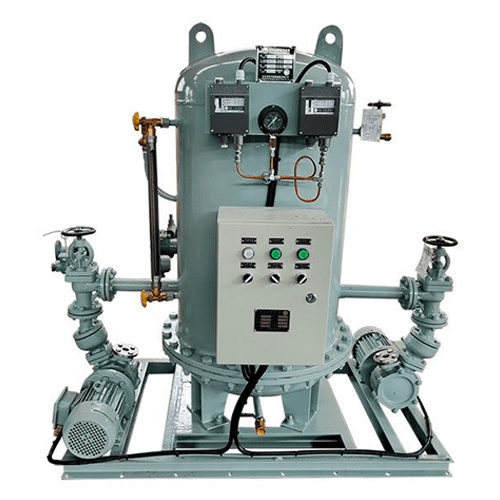

The ZYG Series Marine Hydrophore Tank is designed specifically for ship fresh water pipes and sea water pipes. It is compatible with pumps, pressure switches, electric control boxes, and hydrophones, which are all installed together for seamless operation. With its compact and visually appealing design, this tank is not only easy to install but also simple to maintain. It serves as an ideal unit for water supply systems, providing reliable and efficient water distribution on board ships and vessels.